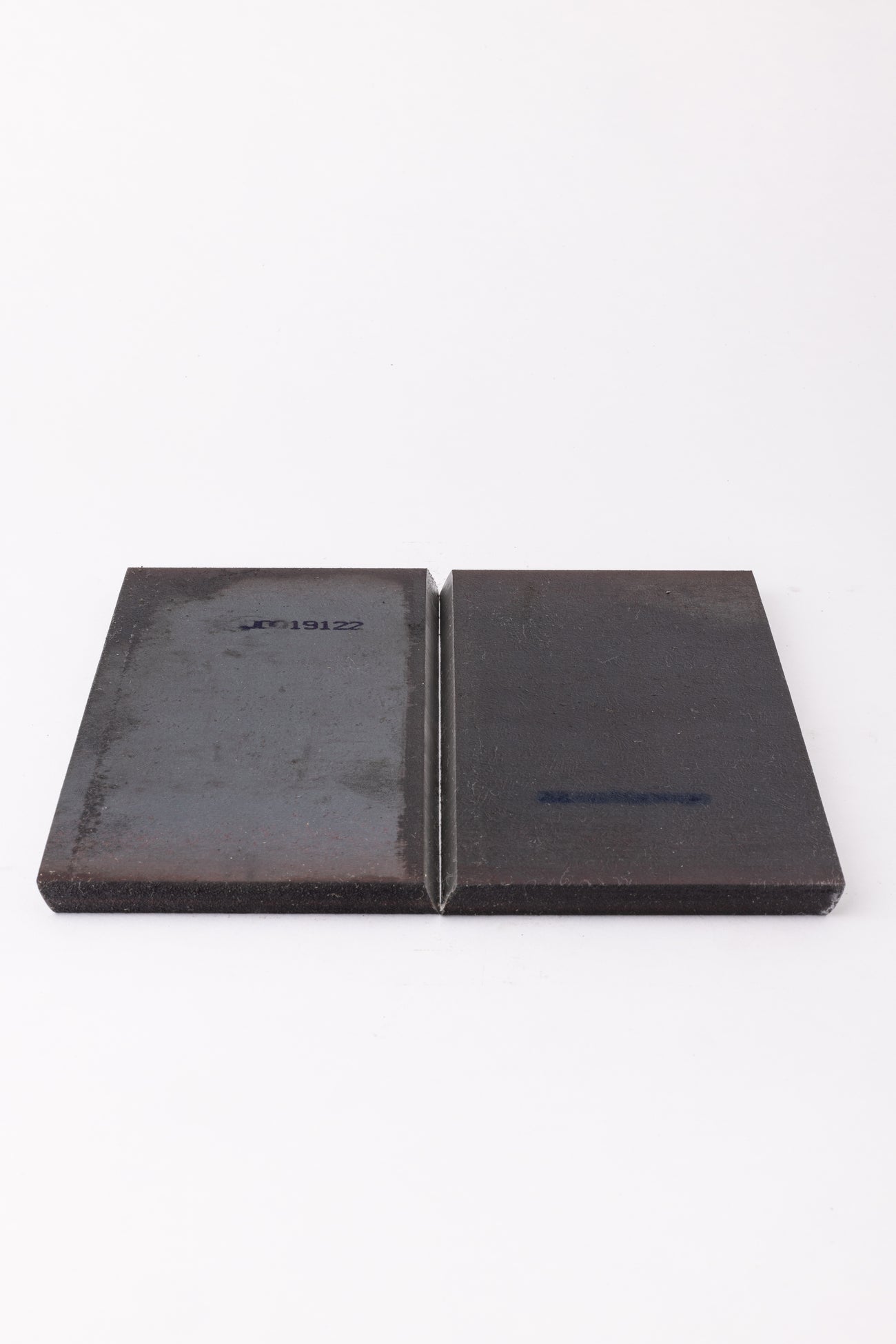

Pipe Coupons

Train and Qualify Welders Quickly and Accurately

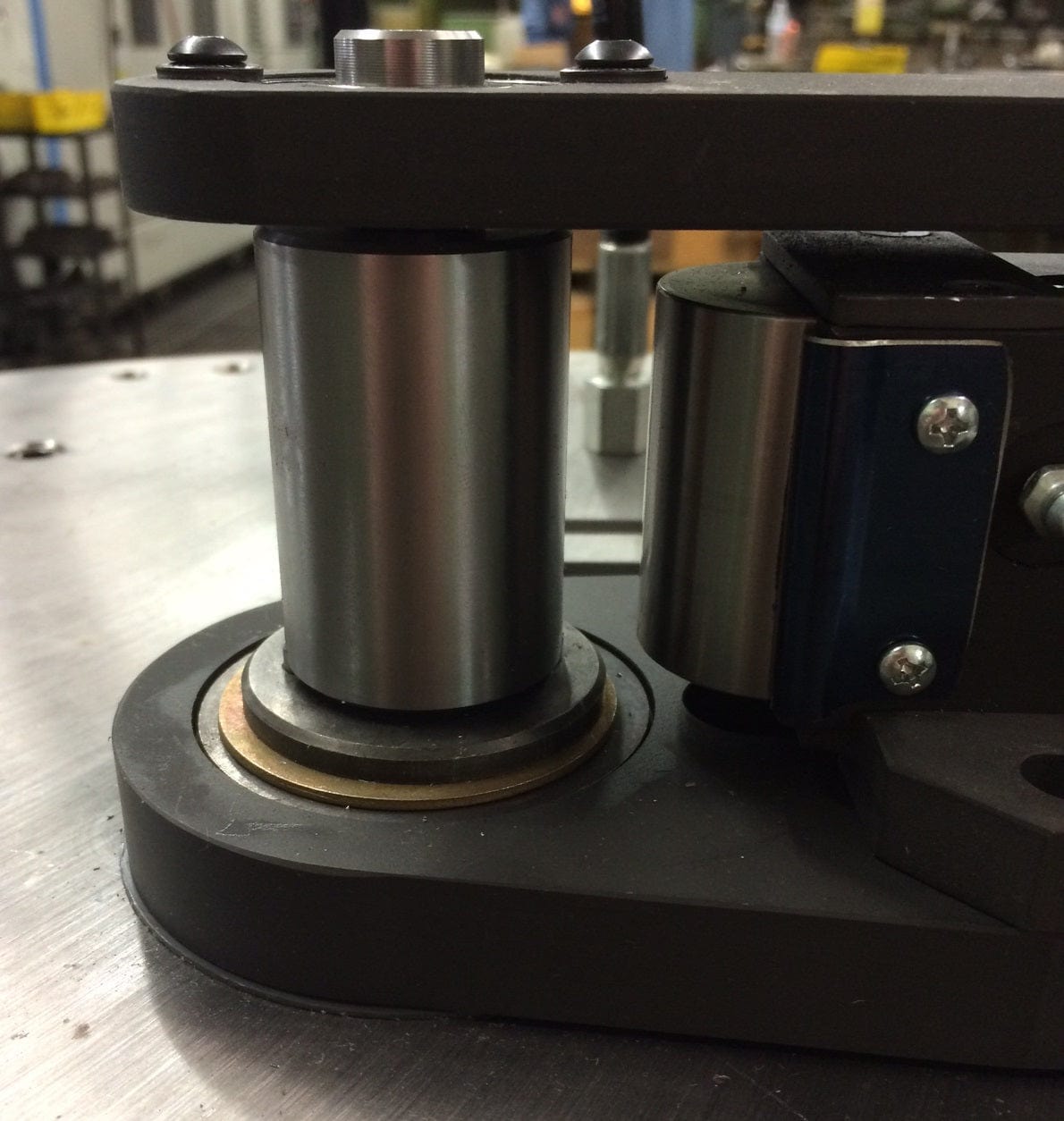

Our line of destructive test equipment expedites the removal and bending of weld test specimens to exact code requirements.

Weld Testing & Qualification Services

In our AWS QC4 Accredited Test Facility we offer complete weld testing services as well as engineering, consulting, and procedural review.

Kevin Penfield | QC Manager/Lead PV Engineer

“I have never ONCE had a form incorrect, coupon lost, coupon material not received in at least 13 years of business. Here’s to many more years of partnership."

Testing Services

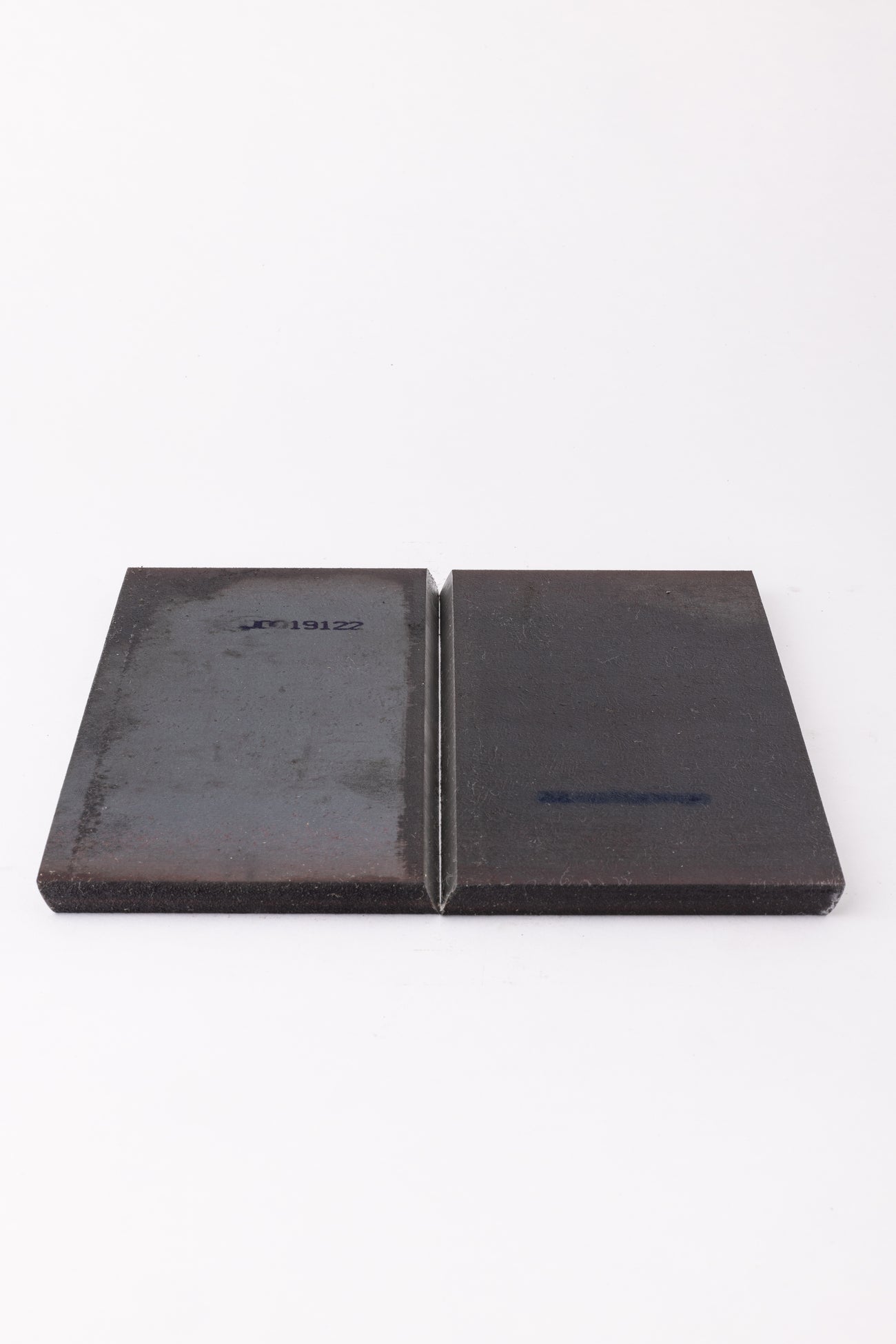

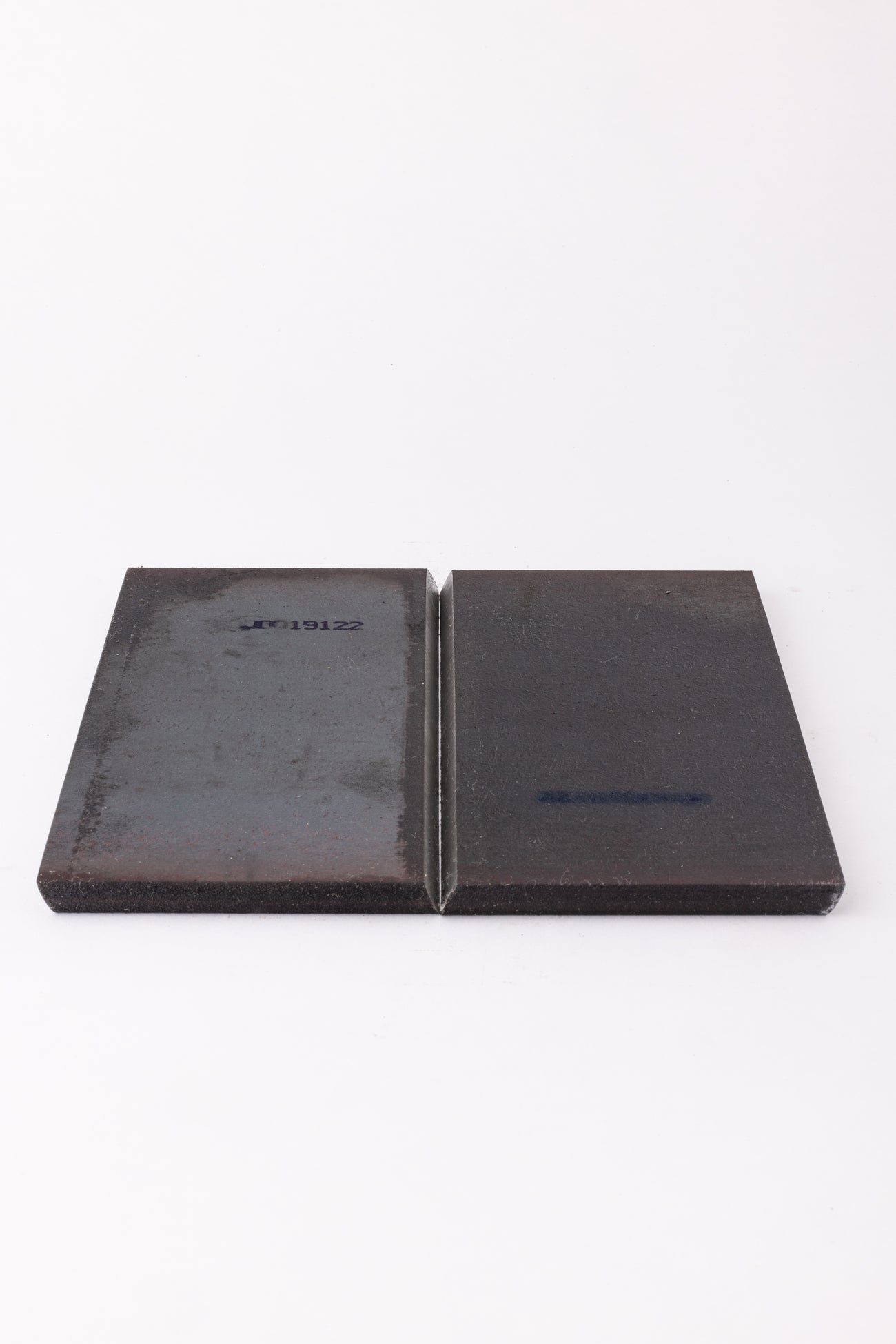

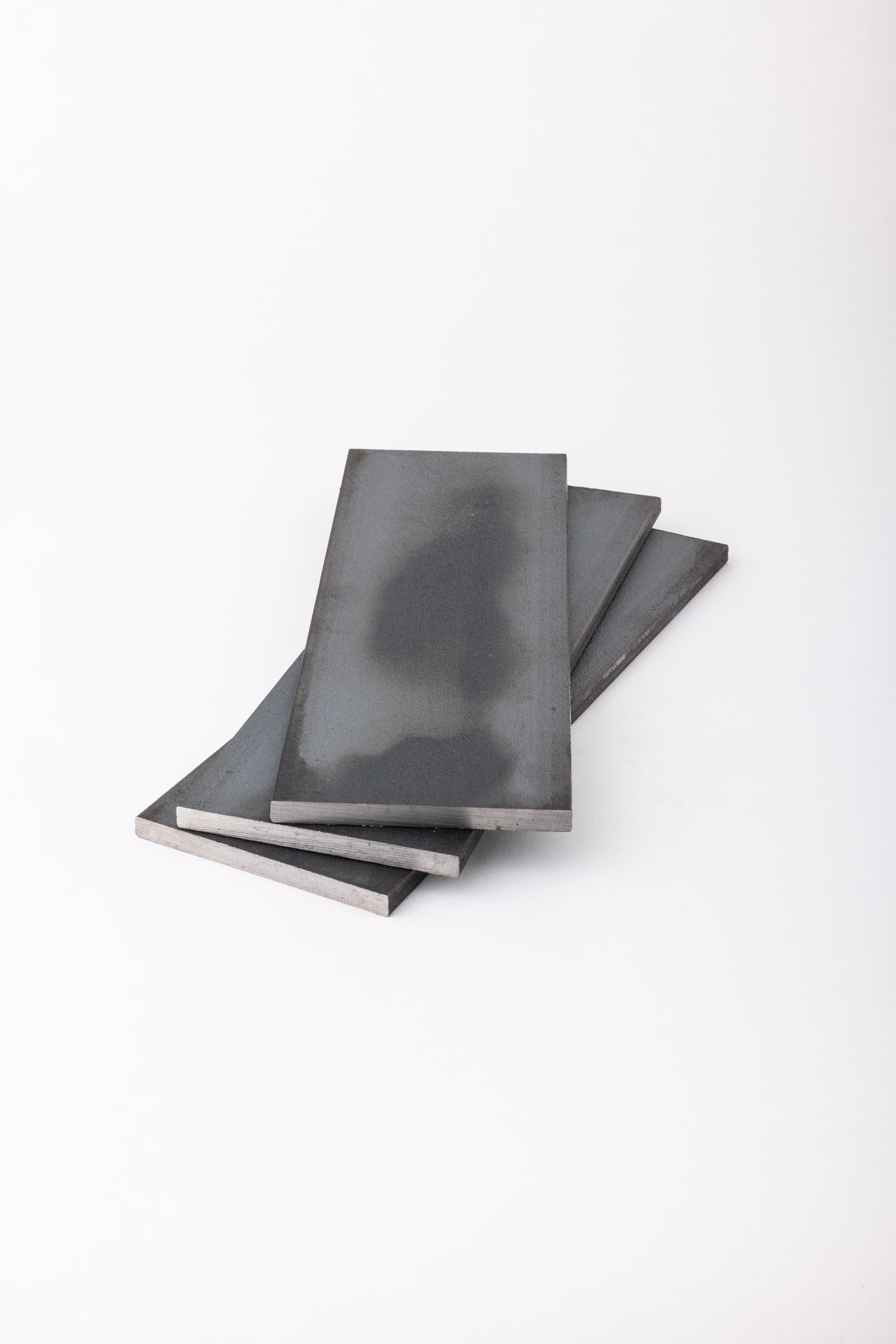

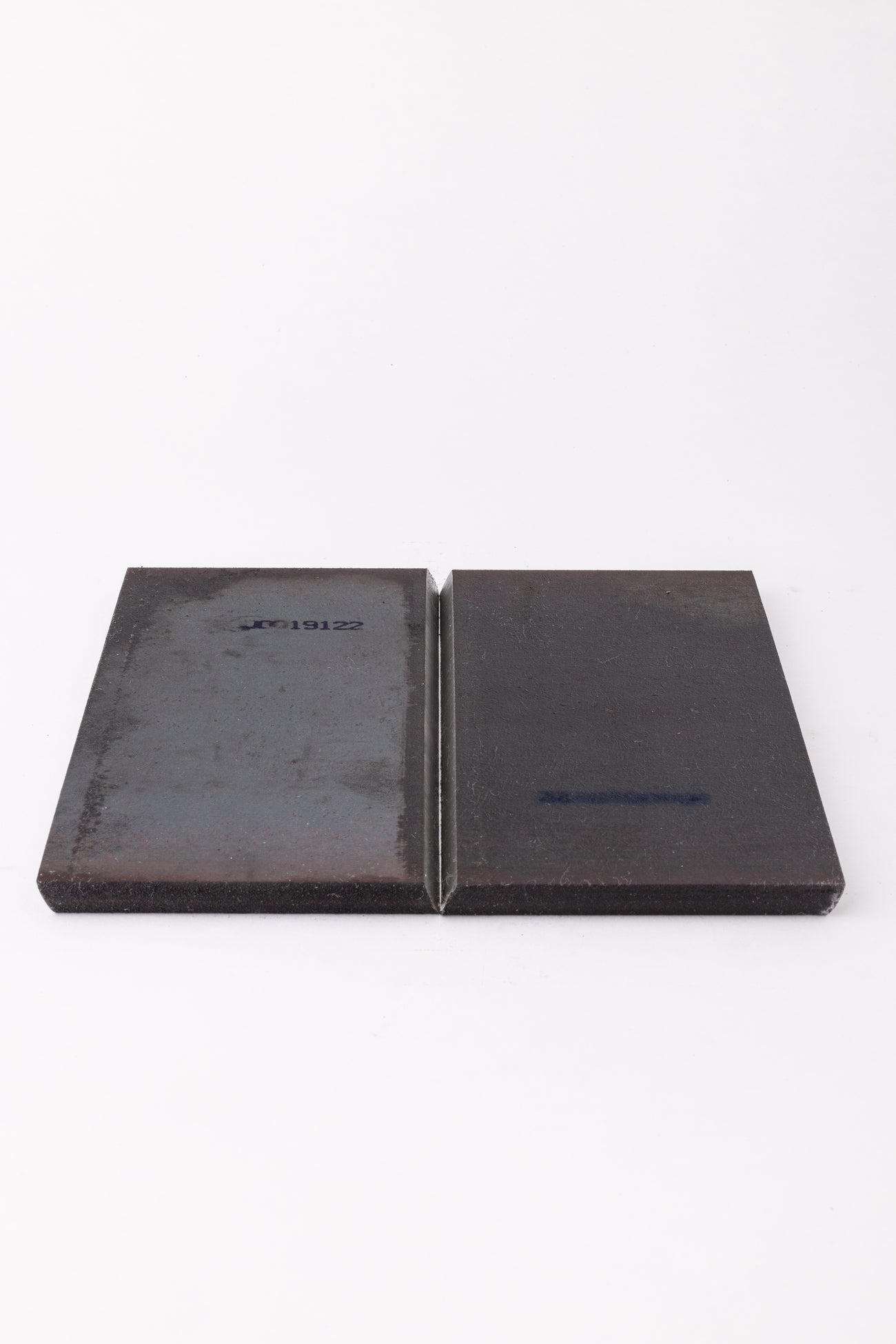

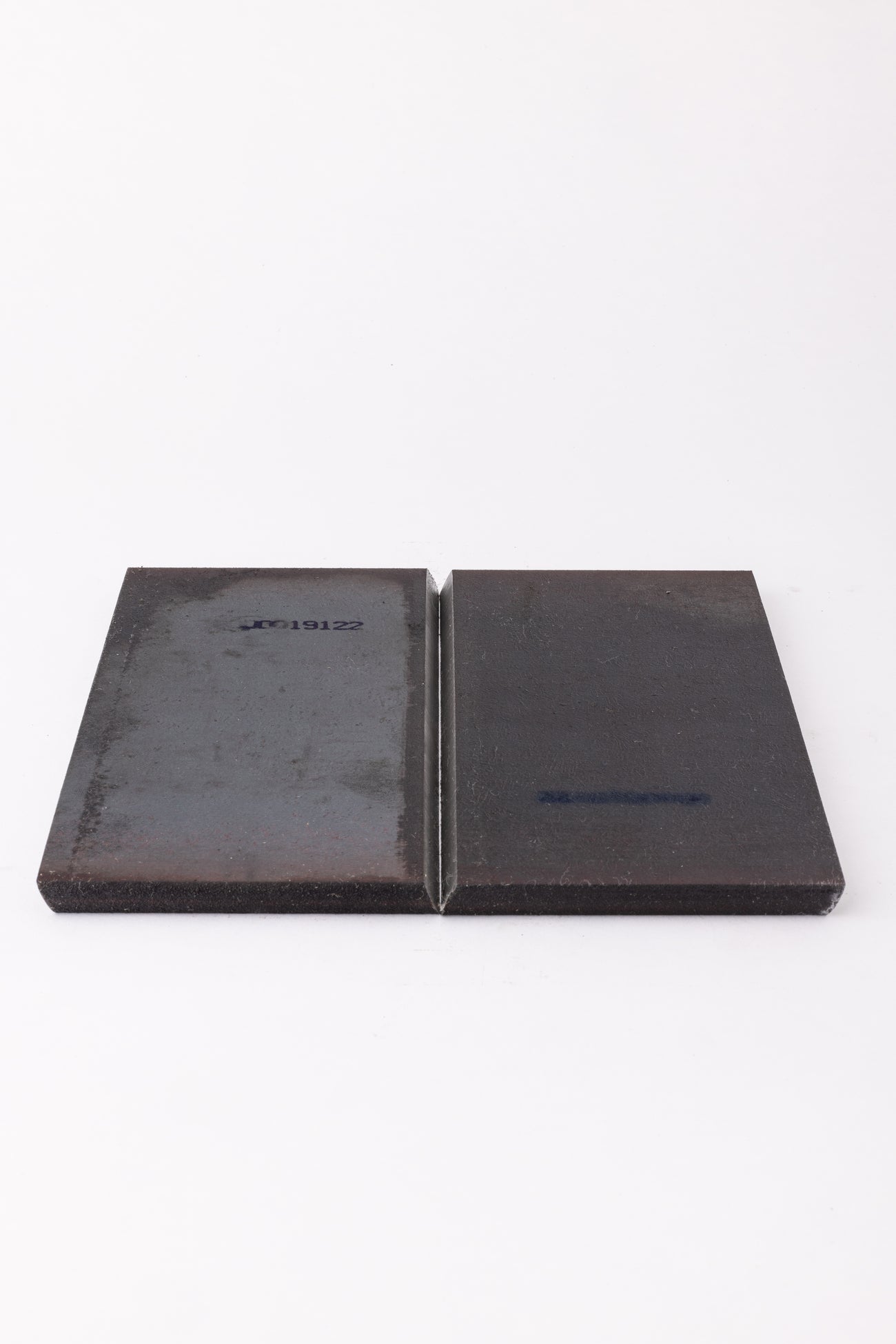

Plate Coupons

Train Fast.

From fit-up to bend test, every Triangle product meets code-ready standards.

Shop NowTest Kits & Combo Boxes

Equipment Parts

Already using Triangle Engineering weld testing equipment? Shop related parts and accessories to keep your operation running smoothly.

Learn more